Aircraft manufacturer Hawker approached S&T Systems to help develop a product that would improve LEAN manufacturing processes and help achieve some key environmental objectives. Hawker required a more consistent and accurate method of applying sealant to the bottom skin of an aircraft’s wing. The aviation developer was using a brush to apply the sealant, which caused over-processing, which resulted in defects within the sealant and led to the build-up of excess waste.

Hawker Aircraft Aero Mini Seal

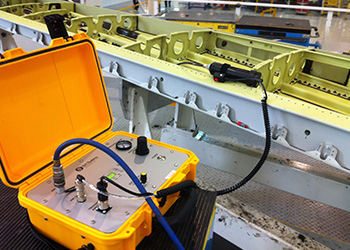

Working closely with the manufacturing team enabled S&T Systems to understand the exact needs of the project. We developed the Aero Mini Seal, a one-shot sealing machine that uses a bespoke nozzle to inject the right amount of sealant directly to the base of the component. The machine has significantly reduced the processing time by 70% and has helped Hawker achieve its environmental objective of reducing sealant waste by 50%.

- A 70% reduction in the processing time

- A 5% reduction in sealant use

- A great improvement in sealant quality

- Achievement of corporate environmental objectives

“We used the machine for the first time in January 2012 and it’s already proving to be an amazing tool, which has greatly improved sealant quality. The standardised sealing process drives LEAN manufacturing in Hawker.”

Rae Carroll, Project Lead

Hawker

If you would like to know more about how S&T Systems can support your organisation, please get in touch.